The manufacturing industry has undergone a significant transformation with the advent of 3D printing technology. Also known as additive manufacturing, 3D printing has revolutionized how products are designed, prototyped, and produced. This groundbreaking technology can disrupt traditional manufacturing methods and unleash a new era of efficiency, customization, and innovation. This article will explore the power of 3D printing technology and its impact on the manufacturing industry. See over here to choose a reliable 3D printing company in Dubai.

Streamlining the design and prototyping phase

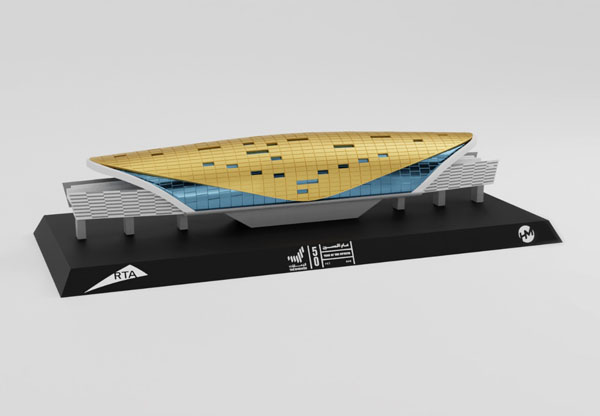

Traditional manufacturing methods often involve a lengthy and costly design and prototyping phase. However, 3D printing technology has revolutionized this process by allowing manufacturers to create prototypes and test designs more efficiently. With 3D printing, complex geometries, and intricate designs can be translated from digital models into physical prototypes with remarkable precision. This enables manufacturers to iterate and refine their designs quickly, reducing time-to-market and costs associated with traditional prototyping methods.

Customization and personalization

One of the most significant advantages of 3D printing technology is its ability to enable customization and personalization on a mass scale. Unlike traditional manufacturing methods that rely on molds or templates, 3D printing allows for producing unique, custom-made products. This level of customization opens up new opportunities for manufacturers to cater to individual customer needs and preferences. Whether it’s creating personalized medical implants, customized automotive parts, or tailor-made consumer goods, 3D printing offers unprecedented flexibility in manufacturing.

On- demand manufacturing and supply chain optimization

3D printing technology can potentially disrupt traditional supply chains by enabling on-demand manufacturing. Instead of relying on centralized production facilities and extensive inventory, manufacturers can produce products closer to the point of consumption. This reduces lead times, transportation costs, and excess inventory, leading to more efficient and sustainable manufacturing processes. Moreover, 3D printing enables decentralized production, allowing manufacturers to respond quickly to changes in demand and adapt their production capacity accordingly.

Complex and lightweight structures

Another significant advantage of 3D printing technology is its ability to create complex, lightweight structures. Traditional manufacturing methods often involve subtractive processes, removing the material to shape the final product. In contrast, 3D printing allows for the creation of intricate and lightweight designs through an additive process. This reduces material waste and enables the production of high-strength, lightweight components that are ideal for industries such as aerospace, automotive, and robotics.